Nylon cable ties, are ubiquitous in both industrial and household applications. They provide a simple yet effective solution for bundling cables and securing objects. However, the production of these versatile tools relies heavily on specialized molds, known as nylon cable tie molds.

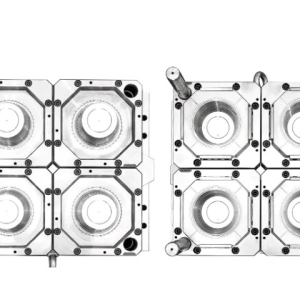

A nylon cable tie mold is designed to shape molten nylon into the desired form of a cable tie. The process begins with the selection of high-quality nylon material, which is heated until it becomes pliable. This molten nylon is then injected into the mold, where it cools and solidifies into the final product. The precision of the mold is crucial, as it determines the dimensions, strength, and overall quality of the cable ties produced.

There are several factors to consider when designing nylon cable tie molds. First, the mold must be engineered to withstand high temperatures and pressures associated with the injection molding process. Additionally, the design should facilitate easy removal of the finished product, minimizing the risk of damage.

Another important aspect is the mold's cooling system. Efficient cooling ensures that the nylon ties are produced quickly and consistently, reducing production time and costs. Advanced molds may even incorporate features that allow for rapid cycle times, enhancing overall productivity.

In conclusion, nylon cable tie molds play a vital role in the manufacturing of cable ties. By understanding their design and functionality, manufacturers can improve production efficiency and product quality, ultimately meeting the growing demands of various industries.