In the fields of building design and construction, as well as heating, ventilation, and air conditioning (HVAC), clamp-on meters are the tools of choice for professionals. Engineers, installers, technicians, and managers of facility operations are all examples of these types of professionals. When used in common applications, clamp-on meters have a low total cost of ownership and provide measurements that are consistently accurate, allowing for precise management of water resources.

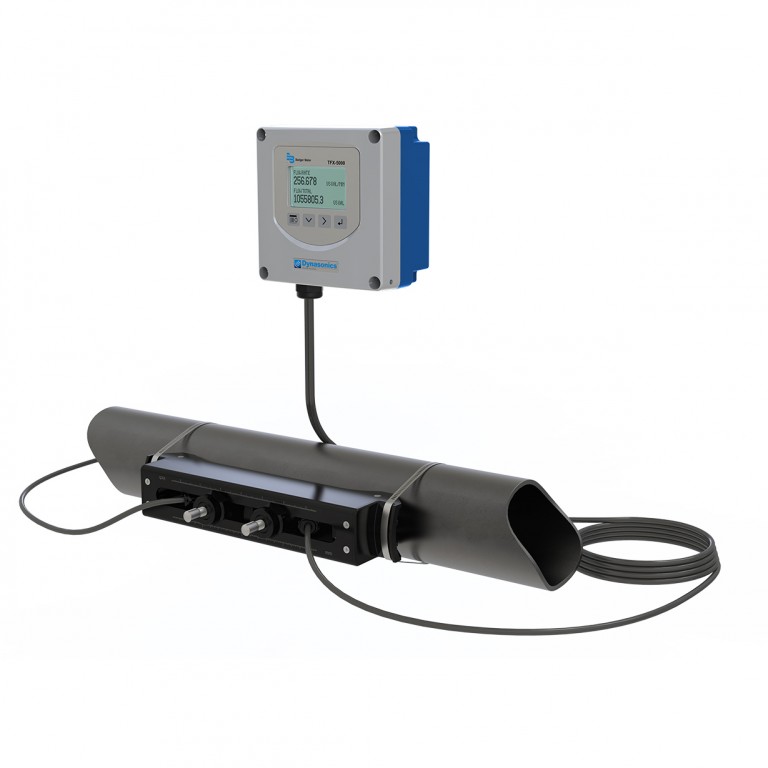

In the realm of flow instrumentation and measurement, the three most common types of meters that are utilized are clamp-on meters, inline meters, and insertion meters. Utilizing ultrasonic technology in either a transit time or Doppler configuration, clamp-on flow meters can determine the velocity of a fluid as it travels through a pipe. This can be accomplished in either configuration. In the fields of building design and construction, as well as heating, ventilation, and air conditioning (HVAC), clamp-on ultrasonic flowmeters are the tools of choice for professionals. Engineers, installers, technicians, and managers of facility operations are all examples of these types of professionals. When utilized in common applications, clamp-on meters have a low total cost of ownership and provide measurements that are consistently accurate, making them ideal for precise water management. For the following four reasons, clamp-on meters continue to be the most popular choice: installation that is simplified, measurements that are accurate, maintenance that is reduced, and a design that is portable.

Improve the efficiency of the installation process.

The installation of clamp-on meters does not require the disruption of service, the cutting into of a pipe, or the stopping of operations. Instead, all that needs to happen is that the meters simply attach themselves to the exterior of a pipe. Because these ultrasonic flow meters completely eliminate downtime and pressure drops, they never come into contact with the fluid, and they can be installed and set up in under an hour, they are an ideal choice for both newly installed systems and retrofits to existing ones. Additionally, they can be installed and set up in under an hour.

More Accurate

For instance, the Dynasonics® Ultrasonic clamp-on meters provide remarkable measurement with an accuracy of up to +0.5% and cover a broad range of flow rates. Even when measuring liquids that contain trace amounts of particulates, or when the temperature, viscosity, density, or pressure are changing, clamp-on meters provide more accurate readings than some traditional meters do. As a consequence of this, a lot of professionals in the HVAC industry opt for clamp-on meters as a long-term solution because they provide more accurate readings than some traditional meters do.

Reduce the amount spent on upkeep.

Clamp-on ultrasonic water meters have a simple design that consists of transducers that clamp onto the pipe and an electronic converter. These two components make up the meter's entirety. Due to the fact that these meters do not have any moving parts and do not come into contact with the internal fluid, the requirement for maintenance is drastically cut down, if not completely eliminated. They do not experience wear and tear over time and do not require frequent calibration, which contributes to a significant reduction in the total cost of ownership when compared to other types of in-line meters. In addition, they do not experience wear and tear over time.

Portable Design

When it comes to checking the flow of another meter or diagnosing problems with it, ultrasonic clamp-on flow meters are extremely helpful due to the fact that their design makes them portable. It is possible to accomplish this goal without interfering with the flow of liquid or making any cuts in the pipe. You can use a single portable clamp-on meter to determine the accuracy of virtually any aging or malfunctioning meter because of the ease with which they can be installed and configured, as well as the fact that they are compatible with a wide variety of pipe sizes. This is possible because of the fact that they are simple to use. Facility managers also make use of them to assist in determining when another meter may be in need of preventative maintenance. This is done by comparing the readings from both meters. Portable ultrasonic clamp-on meters are frequently the most helpful instrument for determining the source of issues and reducing the amount of water that is lost.

How to Figure Out Which Flow Meter Is the Best Fit for Your Application

In the field of heating, ventilation, and air conditioning (HVAC), as well as in the field of building design and construction, flow meters are necessary for a wide variety of applications. The monitoring of water usage for tenant cost allocation and sub-metering is one example of these applications. Another example is measuring flow in cooling tower blowdown and make-up water applications. If you are interested in purchasing a flow meter, it is in your best interest to collaborate with a flow instrumentation specialist who is knowledgeable about the specific requirements of your application and is able to address those needs.

Even though clamp-on ultrasonic flowmeters are a common option for many applications, there may be another flow instrumentation technology that is better suited to guaranteeing the application's ongoing safety, productivity, and profitability. Review the many types that are available, and if you are interested in discussing the possibility of developing a solution that is unique to your needs, get in touch with an authority in flow instrumentation.