Plastic pallets have become an essential component in industries that require efficient material handling and storage solutions. These durable and lightweight platforms are widely used in the logistics, warehousing, and transportation industries. To manufacture plastic pallets, a crucial consideration is the design and structure of the plastic pallet mold.

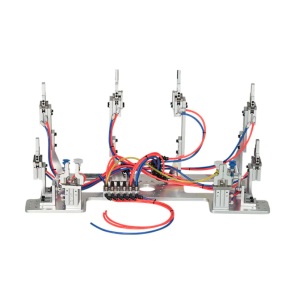

- Cavity and Core:

The cavity and core are the primary components of a plastic pallet mold responsible for creating the shape and dimensions of the pallet. The cavity defines the external shape, while the core defines the internal shape. These two components work together, forming a hollow space that determines the overall dimensions, thickness, and structural integrity of the plastic pallet.

Features:

The cavity and core are typically made from high-quality steel or aluminum. Steel molds offer excellent durability and stability, making them suitable for large-scale production. Aluminum molds, on the other hand, are lighter and provide faster cooling times, making them ideal for small-scale production runs or prototyping. The surfaces of the cavity and core are precision-machined to ensure high accuracy and smooth finishes on the molded pallet.