Multi speed motors, as a type of motor that can flexibly adapt to different working conditions, meet the needs of energy saving, efficiency improvement and application flexibility in many fields by providing multiple speed options. The following is a detailed analysis of the main categories of multi speed motors and their selection considerations.

Variable pole multi speed motor

Variable pole multi speed motor is the typical form of multi speed motor, its core is to adjust the number of magnetic poles inside the motor by changing the connection of the stator winding, and then achieve the change of speed. These motors typically have two or more separate sets of windings, which can be switched between several preset speeds through different combinations of external wiring.

Selection considerations: Suitable for applications that have a fixed demand for speed and do not change frequently, such as air conditioning systems, fans, pumps, etc. Considerations include ease of speed switching, motor efficiency, and balancing initial investment costs with long-term operational savings.

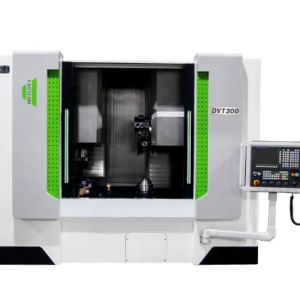

China multi speed motor

Two-speed motor

As a special case of variable pole multi speed motors, two-speed motors offer only two fixed speed options that can be switched between high and low speed by simple circuit switching. It is relatively simple in structure, low in maintenance cost, and suitable for those devices that only need two operating states.

Selection considerations: suitable for those equipment with fixed operation mode, such as auxiliary equipment on some industrial production lines, ventilation systems in buildings, etc. The selection should pay attention to the power matching of the motor, the load characteristics and the reliability of the switching mechanism.

Variable frequency multi speed motor

Although it does not belong to the traditional multi speed motor category in a strict sense, variable frequency motors achieve stepless speed regulation by adjusting the power supply frequency of the frequency converter, and can theoretically reach any speed. This motor is more technologically advanced and can adapt more finely to dynamic load changes, improving energy efficiency and control accuracy.

Selection considerations: Suitable for applications with high requirements for speed regulation continuity, response speed and energy efficiency, such as precision manufacturing and automated production lines. The selection needs to evaluate the cost of the inverter, compatibility and the overall integration complexity of the system.