In today's highly automated industrial environment, small AC induction motors are favored for their efficiency, reliability, and compact design. These motors are widely used in various devices, ranging from household appliances to precision mechanical systems. This article delves into the key materials and techniques employed during their manufacturing.

Manufacturing Materials

Choosing the right materials is critical when manufacturing small AC induction motors. The core components of a motor include the stator, rotor, and housing. The stator typically consists of laminated iron cores with copper windings wrapped around them; the rotor may feature a cast aluminum or squirrel cage structure. The selection of these materials not only influences the performance of the small AC induction motor but also determines its durability and cost.

The stator core is usually made of silicon steel sheets, which have great magnetic properties and help minimize eddy current losses. Copper windings serve as the path for current flow, and choosing high-purity copper helps reduce resistance and improve motor efficiency. For the rotor, a cast aluminum structure is preferred due to its good electrical conductivity and mechanical strength, especially in applications requiring frequent starts and stops.

Manufacturing Techniques

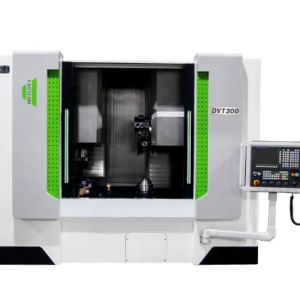

With technological advancements, the production of small AC induction motors has adopted many advanced manufacturing techniques. For instance, automated assembly lines significantly increase production efficiency and consistency. Laser cutting technology allows for more precise processing of stator lamination, reducing assembly errors. Meanwhile, precision casting techniques make the manufacture of rotors more refined, contributing to the overall performance enhancement of small AC induction motors.

Furthermore, to ensure the quality of small AC induction motors, manufacturers employ various testing methods, including vibration testing, noise testing, and electrical performance testing. These tests not only help identify potential issues but also provide data support for subsequent improvements.